Vizag steel Rebar, the Best reinforcement bar for Buildings

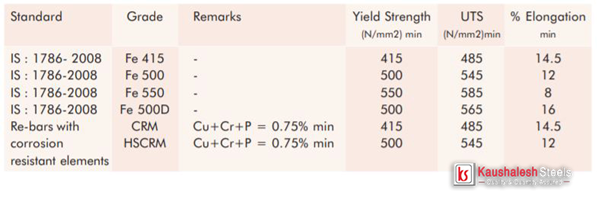

Vizag Steel Rebar Rebar (short for enhancing bar), is a steel bar or mesh of steel wires utilized as a stress tool in enhanced concrete and also strengthened masonry frameworks to strengthen as well as assist the concrete under stress. Concrete is strong under compression, however, has weak tensile toughness. Rebar substantially boosts the tensile toughness of the structure Rebar's surface is usually "warped" with ribs, lugs, or impressions to advertise a much better bond with the concrete as well as reduce the danger of slippage. Quenching of Vizag steel rebars . Quenching and also Self Tempering (QST) passes on a composite micro-framework. varying from a solid, tough, toughened up martensite in the surface area layer to an improved, challenging, ductile ferrite-pearlite in the core with an intermediate framework in between. This makes the Vizag steel rebar the best TMT bar in the market. Unique Functions: Unique Features: 1. Reduced carbon material an